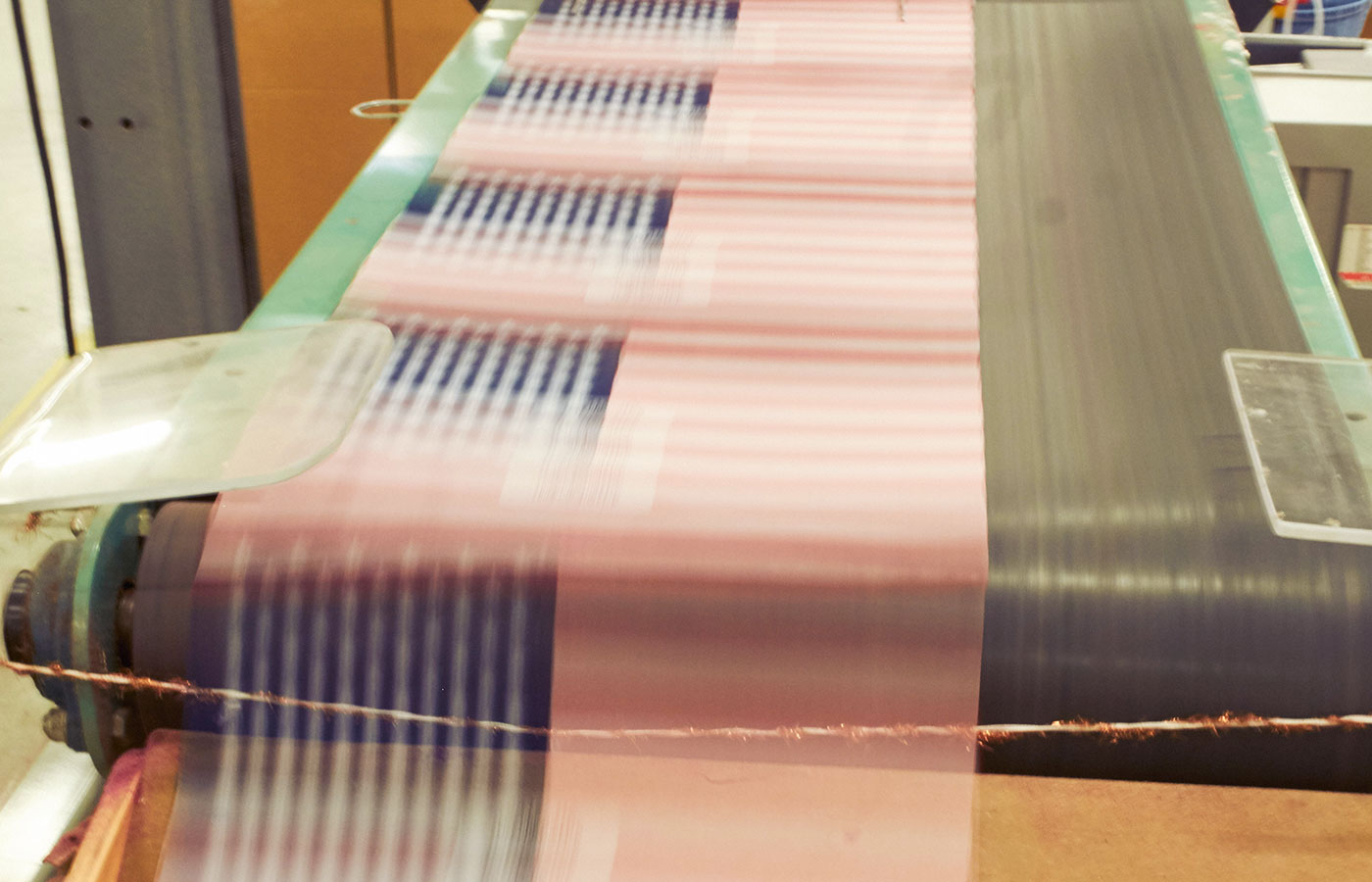

Every day during the first six months of the year is a big day at Annin Flagmakers. The company’s production plant in rural Ohio comes alive at 6 a.m., and the challenge of precision in craftsmanship begins. Demand for Annin’s signature product grows steadily as the Fourth of July comes into view.

Here, the thrum and pulse of sewing machines is a round-the-clock symphony. Director of Operations Dave Rogers oversees a process as dependable as the product, one that is both commonplace and singular in the context of our country: the American flag.

And much like the demand cycles of the patriotic summer holidays that drive this 170-year-old company’s annual output, America itself has driven Annin’s evolution as a business. You might say the two are inextricably intertwined.

An Annin flag flew at President Zachary Taylor’s 1849 inauguration—and has done so at every inauguration since. (Under Taylor’s watch, there were only 30 stars on the flag; there were a full 50 by President John F. Kennedy’s swearing in in 1961.) When, in 1865, the body of President Abraham Lincoln was taken by train from Washington, DC, to Springfield, Illinois, his casket was draped in an Annin flag. Eighty years later, it was an Annin flag that US Marines raised on Mount Suribachi on Iwo Jima, cementing perhaps the most iconic visual of World War II. And Annin flags were taken to the moon during NASA’s Apollo missions from 1969 to 1972.

The company, which today is based in New Jersey and buttressed by two plants in Virginia and a third in Ohio, was founded in 1847 by brothers Benjamin and Edward Annin, who turned their father’s business of crafting flags for the young country’s booming shipping industry in New York City into a bona fide company. (Their lower Manhattan office, at Fulton and William streets, was dubbed “Old Glory Corner” for many years, with stars and stripes signaling the virtues of a growing company and a growing nation.) Demand for the American flag surged when the Civil War broke out and continued to grow as World War I drew American soldiers across the globe. The 20th century eventually saw the rise of a consumer market in which American families flew the flag outside living room windows in a rapidly expanding suburbia. Since then, Annin has remained the largest American flag manufacturer in the industry.

Maintaining its position at the top of the business only got harder after the September 11 attacks, which produced an outpouring of patriotic sentiment and an unparalleled demand for the flag. In the wake of the attacks, there wasn’t a flag manufacturer in the US that could keep up. “When there’s a situation like that,” says Mary Repke, the company’s senior vice president of marketing, “Americans want to show their pride and their strength.”

In fact, demand was so high that foreign companies began flooding the market with flags. Annin and its few American competitors banded together to form the Flag Manufacturers Association of America, a trade group that issues a special mark certifying that a flag is made in the USA and asks Americans to look for it before they buy a flag.

In total, Annin’s three factories produce around 10 million flags annually, from the small stick versions children wave alongside parade routes to the imposing 30-by-60-foot behemoths that flap in the wind above sprawling auto dealerships. While some smaller flags have their patterns printed directly onto white material, the cut-and-sewn models are made from three main components: the short stripes, the long stripes, and the field containing the 50 stars. In compartmentalized sewing cells, men and women work at rapid clips to stitch the short stripes to the field, and then stitch that piece to the long stripes. Finally, the heading and grommets are added before placing an FMAA stamp on the finished product. Carter Beard, a sixth-generation Annin family member and the company’s president and CEO, credits continual upgrades in sewing and printmaking technology with Annin’s ability to keep pace with the post-9/11 demand.

“We’ve invested heavily in the company to modernize production,” Beard says.

And while the American flag is the marquee product, making up two-thirds of the company’s production, Annin also crafts the POW-MIA flag (which it designed in-house in the 1970s), all 50 state flags, and 196 United Nations–recognized country flags. No longer included: the Confederate flag, which was previously produced primarily for Civil War re-enactment groups. Another flag, serving as a mark of pride for the nation’s LGBT community, has grown in popularity. “In one week, we saw the Confederate flag go down and the rainbow flag go up,” Repke says.

Stitch by stitch, Annin has helped document the development of American culture and society, occupying a unique front-row seat to the nation’s growth. It’s a story that the company is proud to help tell.

“The fiber of the American public is that we rally and we stand strong,” Repke says. “That’s where most Americans put that symbolism.”

MORE: Read about the original Star-Spangled Banner—the flag that flew over Fort McHenry during the War of 1812 and went on to inspire our national anthem—the restoration of which Ralph Lauren helped fund &- ALL PHOTOGRAPHS BY JACK O’CONNOR